Learn Piping Design

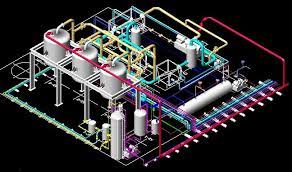

Piping is a highly specialised branch of mechanical engineering. It has applications in oil and gas refineries, metal and mining plants etc. Where ever fluid at considerable temperature and pressure needs to be safely transported from one point to another. The design of piping is critical for the smooth functioning and safe operation of any plant. Piping accounts for around 35% of the initial fixed cost next to process equipment. It also consumes 50% of field labour. The science behind piping is therefore extremely important and must be well understood.

The most common type of pipe in industrial plants is round steel or carbon steel, although stainless and aluminium piping are also used. Round steel piping is manufactured in several different grades. These include a low pressure grade for general use, a medium pressure grade for pressurised liquids and gases and a high pressure grade for super critical fluids such as steam.

For many years, round steel piping has been the preferred option for chemical and gas processing plant piping design due to its strength, reliability and safety features. However, in recent times a number of companies have come out with new pipe materials which have improved on the performance of round steel and offer a range of benefits including reduced risk of leakage and lower total installed costs.

How to Learn Piping Design

Various factors influence the choice of pipe material for a particular application, but the most important considerations are corrosion resistance, ease of fabrication and installation, weight, strength, pressure rating, temperature rating, service conditions and cost. There are also a number of different methods to connect piping components which are determined by the required level of service, environmental conditions, and the availability of suitable fittings.

These connections include nipples (closed joints), couplings, elbows, tees, crosses and return bends. Closed nipple joints are threaded on both ends and utilise internal sealing to prevent fluid leakage, whilst couplings allow two pieces of pipe of the same size to join together without requiring the use of tools. Elbows and tees allow for branch line connections at 45° and 90o respectively, whilst returns bends can be used to reverse the direction of a pipe run. Other piping components include bushings (which can be used to connect pipes of different sizes) and plugs (used to close off open piping ends or fittings).

This course provides participants with practical knowledge and skills on the fundamental concepts and principles of plant layout and piping design. This includes understanding the physics of fluid flow and its application in piping, good piping layout practices and why piping systems fail. It will also provide an overview of the piping design life cycle, identifying key decisions and calculation requirements. The course will prepare engineers to apply best practice piping methodologies in designing systems that are cost effective, constructable and safe during the design and construction phases of a project.