Alumina PCBs Suitable For High-Power

Alumina PCBs are a type of printed circuit board that uses aluminum oxide (Al2O3) ceramic as the substrate material instead of the more common FR-4 laminate. Their combination of electrical, thermal, and mechanical properties makes them suitable for specialized applications that require high-power density electronics, heat dissipation, and survivability in harsh environments.

The alumina ceramic material is an excellent conductor of electricity. Its crystalline structure allows for low resistance and high conductivity between layers. It is also highly durable and resists chemical attack. Additionally, alumina is not prone to cracking or breaking like fiberglass boards. It can be used in high-power RF transmitters that are exposed to intense heat and vibrations.

Unlike FR-4, alumina pcb does not absorb moisture. This is important because moisture can lead to the formation of oxidation stress, which can cause significant damage to the circuit board. Additionally, alumina is not susceptible to the same aging issues that FR-4 can have, which can cause it to become unstable over time.

Are Alumina PCBs Suitable For High-Power RF Transmitters?

Alumina is a good choice for high-power RF transmitters, as it can disperse the heat that is generated by these devices, preventing them from overheating and causing damage to the components on the board. This feature of alumina is what makes it such a valuable material for high-power RF transmitters.

Additionally, alumina is much more resilient than other materials such as glass and epoxy. This is because it has a much higher melting point, which makes it easier to handle and fabricate. Furthermore, alumina is also not as porous, which means that it will not allow harmful contaminants to seep through and damage the circuit board.

Alumina PCBs are often used for aerospace and defense applications. They are able to withstand harsh environmental conditions and mechanical stresses, which helps them maintain their integrity. These boards are typically more expensive than FR-4 PCBs, but they can be worth the investment for those who need a high-performance, reliable product.

Alumina is also a good choice for electronic assemblies that are subject to corrosive chemicals. These circuit boards can be hermetically sealed, which protects them from ingress of moisture and other chemicals. In addition, they can withstand high amplitude vibrations and shocks that would fracture conventional PCBs.

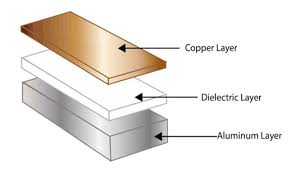

The alumina PCB manufacturing process involves laminating and bonding alumina ceramic layers together before firing them to transform them into a solid. The resulting circuits are then soldered using high-temperature metals. In addition, alumina has great insulating properties, which prevents them from transferring thermal energy to adjacent layers. Lastly, the alumina substrate has good conductor adhesion and can be used with a variety of coatings. This makes it possible to create complex embedded layouts. These layouts can include mezzanine modules, microwave cavities, and more. Moreover, alumina can be used with various surface finishes, such as immersion silver and immersion tin. These coatings make it easy to solder components onto the board. Finally, alumina has a very high mean time between failures (MTBF) due to its tight manufacturing tolerances.