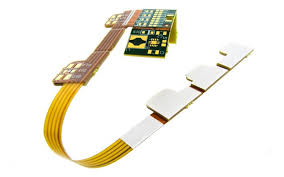

Flexible Circuit Boards

Flexible PCBs (also known as flex circuits) have multiple layers and are designed to bend and flex. This makes them ideal for use in many different types of applications. They can be used in consumer electronics such as LED strips, interfaces and cameras in smartphones and tablets. They can also be found in automotive products such as sensors, fingerprint and facial recognition modules. These flexible circuit boards consist of a dielectric substrate film, copper traces and adhesive materials. Depending on the requirements of your design, the thickness and other characteristics of the board can vary significantly.

A conductive layer of copper is bonded to a dielectric layer, usually made of polyimide or polyester. The traces create the electrical pathways on the PCB, and it is important to choose the right type of copper and bonding methods for this purpose. The choice of materials will have a significant impact on the cost and reliability of the board.

The copper traces are a vital part of any flexible circuit board, and they need to be carefully designed to ensure their durability and flexibility. A good starting point is to use a wide trace width with thin endpoints. This will allow the traces to be easily bended without damaging the copper or the dielectric. It is also advisable to stagger the copper traces on different layers of the board. This reduces the likelihood of breaks or cracks in the copper during bending and allows you to bend the PCB with more accuracy.

Components Attached to Flexible Circuit Boards

Flex PCBs need to be able to withstand a variety of environmental factors such as humidity, chemicals, shock and vibration. In order to achieve this, it is essential that the material properties of the traces and copper are accurately modeled. This will help in determining the product’s durability and minimum allowed bending radius. The use of rolled annealed copper rather than electro-deposited copper can also improve the ductility of the circuit.

In addition to the conductive and insulation layers, flexible circuits have vias (also known as holes) that pass through them from one side to the other. Vias are necessary to connect the conductive layers and provide an avenue for the flow of electricity in a flex PCB. Vias can be plated with gold, nickel or silver to increase their longevity. It is a good idea to keep the number of vias to a minimum as this will decrease production costs and make it easier for manufacturers to drill them.

In addition to these design considerations, it is a good idea to use an online calculator to see how much your design will cost. This is particularly important for flex PCBs as they can be more expensive to produce than rigid circuit boards. PCBway has a detailed calculator that will give you a precise estimate of the manufacturing cost of your flex circuit. In addition, you should use a turnkey manufacturer to ensure that all processes are done at the same facility to avoid multivendor miscommunication.